Overview:

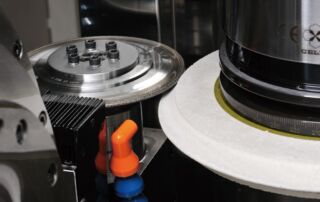

Toolink Engineering is proud now to introduce the Matrix GH-3540 220G. Built on a stable frame structure and using traditional methods of manufacture the Matrix GH-3540 220G offers high levels of accuracy and rigidity.

The Matrix GH-3540 220G Gear Form Grinding Machine applies FANUC controls and a high-speed grinding spindle, through the Matrix developed intelligent conversations window the software supports the complete machining process. The machine can generate an NC program automatically through input parameters and the setting of grinding conditions via the conversation, improving efficiency and ease of programming for the machine operator.

Machine capabilities include involute and cycloidal gears.

Gear grinding machines built to customer specifications and Matrix standard models are shipped as turnkey solutions. Toolink Engineering will provide installation and training with each purchase.

Matrix GH-3540 220G Highlights

MIN/Max Workpiece Outside Diameter 30mm – 400mm

Max Module M8(DP3.2)(Diamond Point Dresser)M12(DP2.1)(Diamond Rotary Disc Dresser)

Teeth Range 9~999

Max Tooth Depth 27mm

Helix Angle ±45°

Technical Data

Notes: It is strongly advised to keep the machine in a controlled temperature environment. I.E. temperature control between 20°C ~ 26°C ±1°C will achieve gear Grade 4 to DIN 3962 and Grade 5 in the event of mass production.

The specifications are subject to the contract, as well as new technology and industrial advancements available.

About Matrix Machine Tools

Matrix Machine Tool (Coventry) Limited, has been a leading manufacturer of high-quality external and internal thread grinders since 1934. In 2017, Matrix introduced 7 new gear grinding machines to the world market. Like our internal and external thread grinders, Matrix gear grinding machines are intelligently designed and built using premium components and high-quality construction. Matrix gear grinding machines are driven by FANUC or Siemens controls and feature-rich software to facilitate programming and usability. Through this customer-focused approach, Matrix has garnered a global reputation for its gear grinding machines’ accuracy, performance, and longevity.

Get Social