Overview:

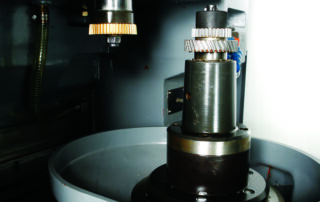

Toolink Engineering is thrilled to represent S&T DYNAMICS and their P250. The P250 CNC Gear Shaping Machine enables easy and efficient operation. Heavy cutting is possible due to the use of high-strength columns and counter columns. CNC controls enable automation and provide convenient operation by GUD (Global User Data) environment.

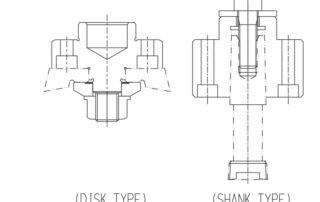

- Shaping Head – High-Precision Hydraulic Static Pressure Guide – Superior cutting stability and vibration reduction are provided. Precise run-out of the head is guaranteed by applying a high-precision hydraulic static pressure guide and metal bushing to the shaping head.

- Dual Lead Worm – By using a precision dual lead worm (less than 10㎛ transmission error) to treat shaping head and table index worm, it is possible to achieve fine control on backlash while guaranteeing excellent precision for gear processing.

- GUD (Global User Data – Interactive Programming Environment – By utilizing the interactive programming environment of GUD (Global User Data), additional programming is not necessary and gear processing is easy with just the input of specifications of hob cutter, workpiece, and cutting

condition.

S&T Dynamics P250

- Siemens / FANUC / Sentrol

Max. Workpiece Diameter Ø250

Max. Workpiece Module M6

Spindle Motor: 3.7/4.9 kW

Max. Number of Strokes: 700 str/min

Max. Cutting Stroke: 65 mm

Magnetic Chip Separator

P250 Accessories

Technical Data

Notes: Gear shaping machines built to customer specifications and S&T Dynamics standard models are shipped as turnkey solutions. Toolink Engineering will also provide installation, training, and support with each purchase.

Video Overview

S&T Dynamics is a full service, turnkey manufacturer of CNC machine tools and engineered solutions

![]()

About S&T Dynamics

Based in Gyoungnam, Korea, S&T Dynamics, in addition to machine tools, is a leading automotive and military powertrain, axles, and transmissions that include gearboxes for helicopters, wind-power applications, dual-clutch transmissions, and hybrid power trains. It also supplies both civil and military aerospace, medical and general sectors.

Gear hobbing machines built to customer specifications and S&T Dynamics standard models are shipped as turnkey solutions.

Get Social