Overview:

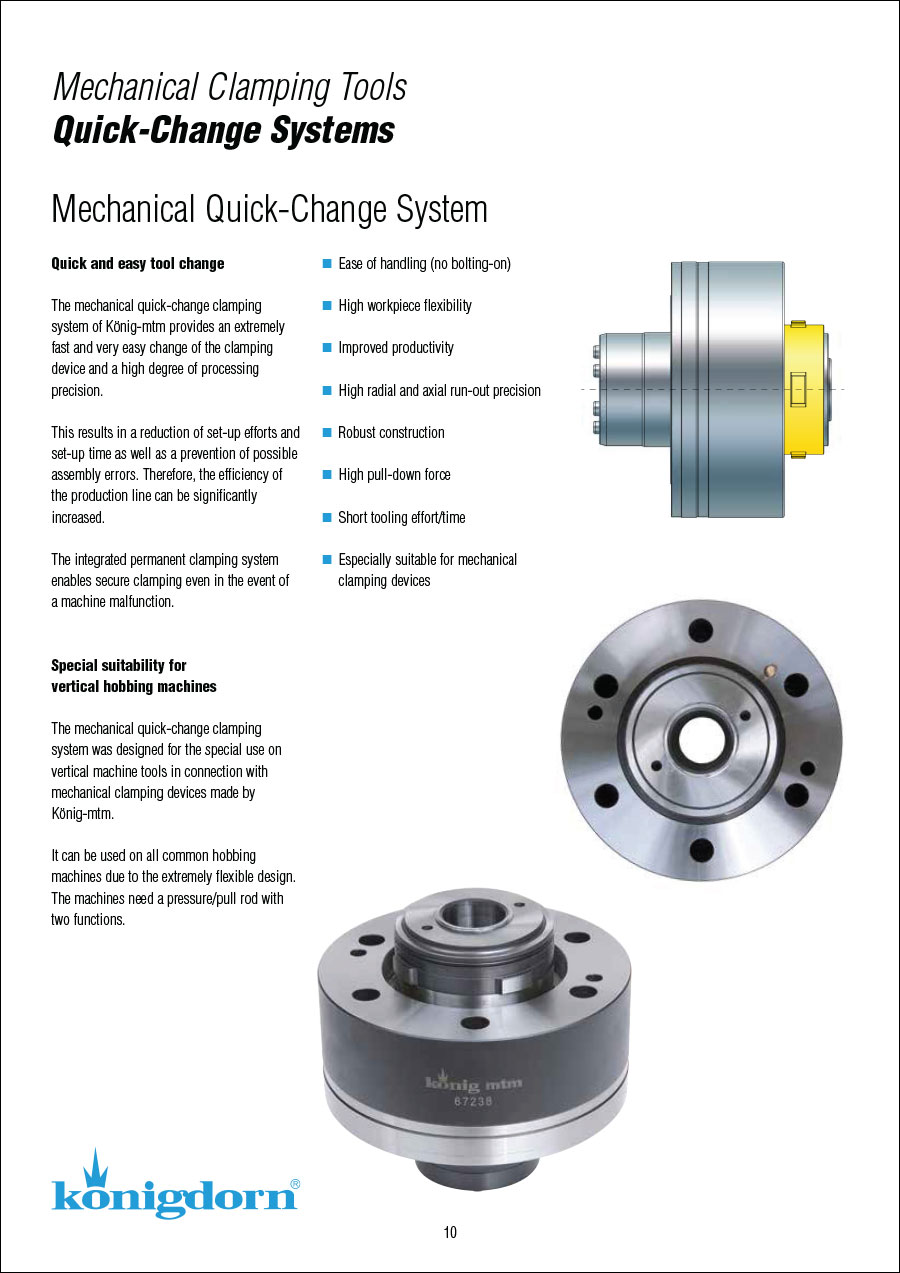

König’s mechanical quick-change clamping system provides an extremely fast and easy change of clamping devices and provides a high degree of processing precision.

This results in a reduction of set-up efforts and set-up time as well as the prevention of possible assembly errors. Therefore, the efficiency of the production line can be significantly increased.

The integrated permanent clamping system enables secure clamping even in the event of a machine malfunction.

Special suitability for vertical hobbing machines:

The mechanical quick-change clamping system was designed for special use on vertical machine tools in connection with mechanical clamping devices made by König.

It can be used on all common hobbing machines due to the extremely flexible design. The machines need a pressure/pull rod with two functions.

Get Social