Overview:

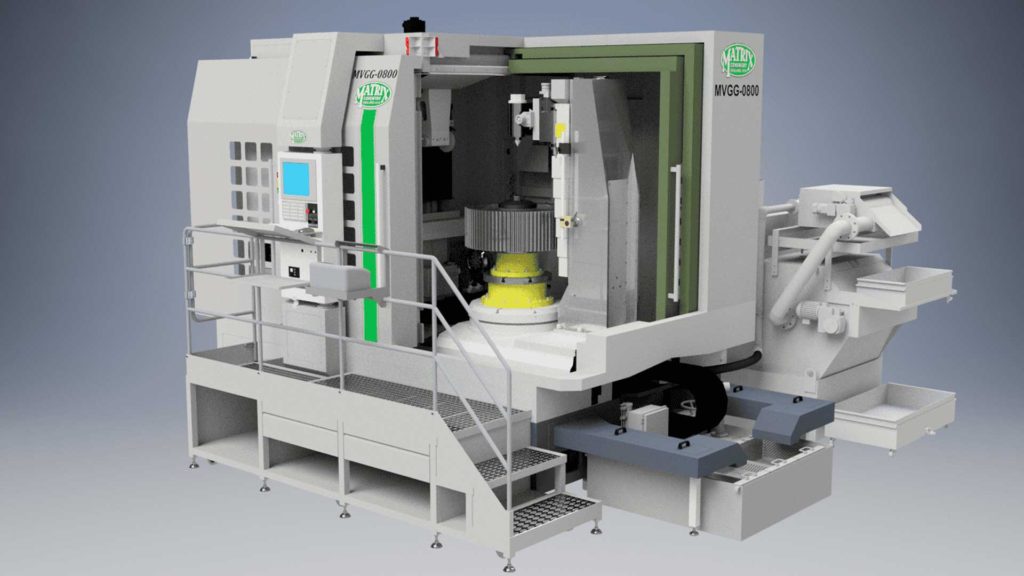

Toolink Engineering is excited to present the latest addition to our lineup: the Matrix MVGG-0800 Vertical Gear Form Grinding Machine. Designed to meet the demands of modern gear manufacturing, this machine offers unparalleled versatility and precision. Capable of producing large gears with exceptional accuracy, the MVGG-0800 is the perfect solution for a wide range of applications in industries such as aerospace, automotive, and more. What sets this machine apart is its ability to grind hob cutters, further expanding its utility and making it a truly indispensable tool in any machining arsenal. With its advanced technology and robust construction, the Matrix MVGG-0800 delivers superior performance and reliability, ensuring optimal results with every operation. Trust Toolink Engineering to provide you with the tools you need to stay ahead in today’s competitive market.

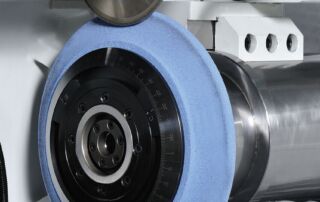

Included as a standard feature, the Matrix MVGG-0800 Vertical Gear Form Grinding Machine is equipped with a FANUC control system, paired with a high-speed grinding spindle, harnessing the power of Matrix-developed intelligent conversational windows software to provide unmatched flexibility in output. This innovative software enables precise control over tooth profile and grinding parameters, ensuring optimal results with every operation. The machine’s worktable is designed to accommodate a variety of workpieces, including Involute Gears, Cyclonical Gears, and large-module Hobs, making it a versatile solution for a wide range of gear manufacturing applications.

Gear grinding machines built to customer specifications and Matrix standard models are shipped as turnkey solutions.

MVGG-0800 Highlights

- FANUC Controls

Max Workpiece Outside Diameter 800mm|31.4″

Teeth Range 9~999

Min Workpiece Root Diameter 50mm|1.9″

Module M2.0~M20|DP12.7~DP1.27

Max Tooth Depth 45mm| 1.7″

Helix Angle ±45°

Parts Gallery

Technical Data

Notes: It is strongly advised to keep the machine in a controlled temperature environment. I.E. temperature control between 20°C ~ 26°C ±1°C will achieve gear Grade 4 to DIN 3962 and Grade 5 in the event of mass production.

The specifications are subject to the contract, as well as new technology and industrial advancements available.

About Matrix Machine Tools

Matrix Machine Tool (Coventry) Limited, has been a leading manufacturer of high-quality external and internal thread grinders since 1934. In 2017, Matrix introduced 7 new gear grinding machines to the world market. Like our internal and external thread grinders, Matrix gear grinding machines are intelligently designed and built using premium components and high-quality construction. Matrix gear grinding machines are driven by FANUC or Siemens controls and feature-rich software to facilitate programming and usability. Through this customer-focused approach, Matrix has garnered a global reputation for its gear grinding machines’ accuracy, performance, and longevity.

Get Social