Overview:

MET Edge Prep Systems are intended to offer something for everyone in the way of automated edge prep. From the very basic MET Manual to the MET-6 Auto Load, precise and high-quality automated edge prep is the focus of all the systems and capabilities, and the various options we provide make them a top choice for all types of shops and budgets.

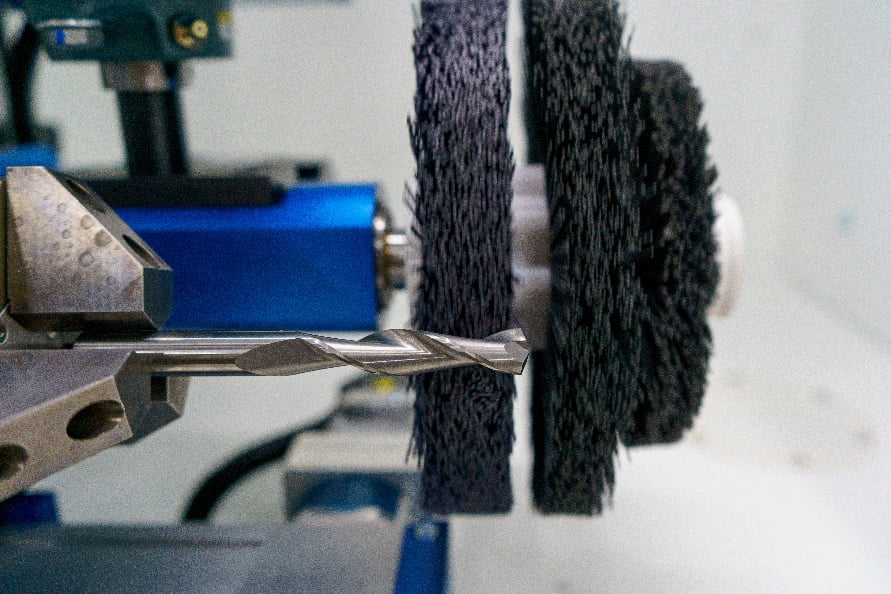

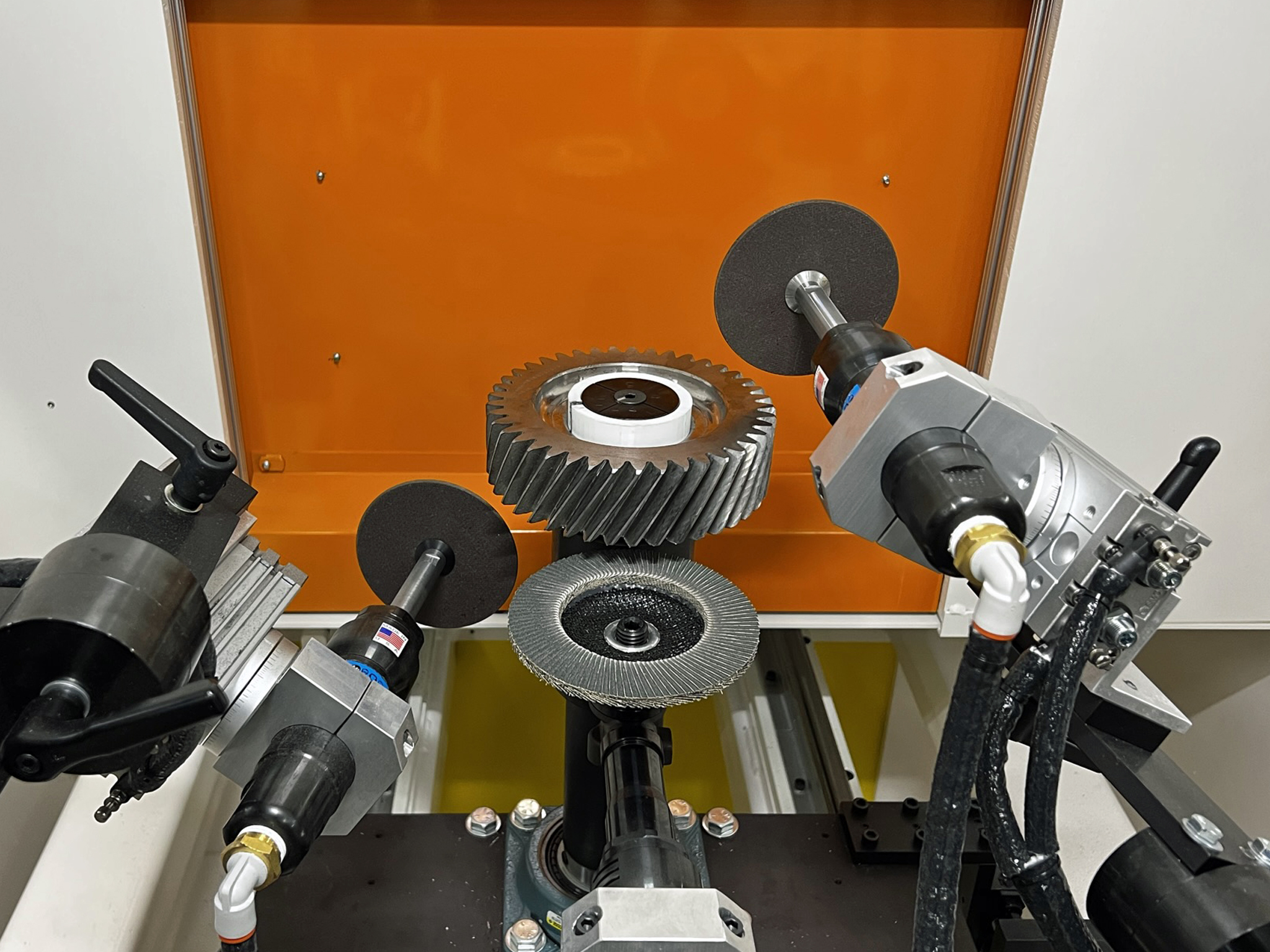

As a universal yet specialized machine, our solutions are designed to generate an edge prep on a large variety of tool types. Our units can process drills, reamers, end mills, step drills, and hobs, as well as many other specialty-type tools. Our machines accept hobs and end mills up to 10” long and 6” in diameter. Drills of most types and styles can be prepped by matching the angle of the cutting face.

Machine controls allow the operation of MET Edge Prep tool by anyone within a few hours. The conversational operator interface allows the operator to select the tool type, diameter, length of flute (on round tools) angle of drill tip (on drills) type of edge prep such as a full radius, waterfall or reverse waterfall and size of the radius. By selecting these parameters, the machine automatically adjusts itself to produce the end results. In addition, using the “custom-cycle” feature, the machine can be set up to allow a user-specific or unusual edge prep beyond the scope of the standard available sequences. Appropriate password protection is installed for various levels of access.

MET Edge Prep Highlights

Highly Versatile Applications

Easy to Use Conversational Operator Interface

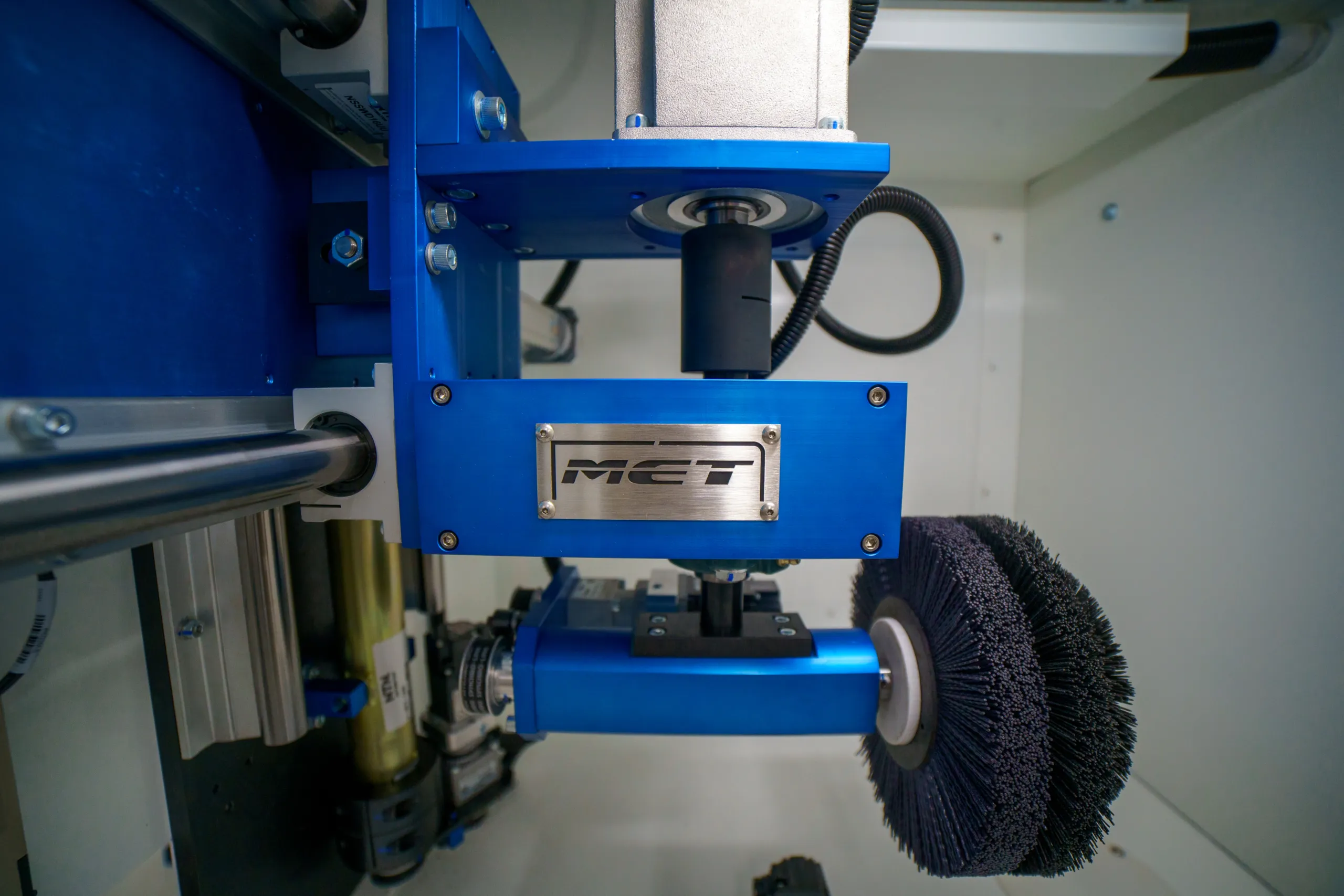

Nylon Abrasive Radial Brushes

Specialty Brushes Available

Suitable for a Diverse Selection of Parts

Many Options Available

MET Edge Prep Benefits

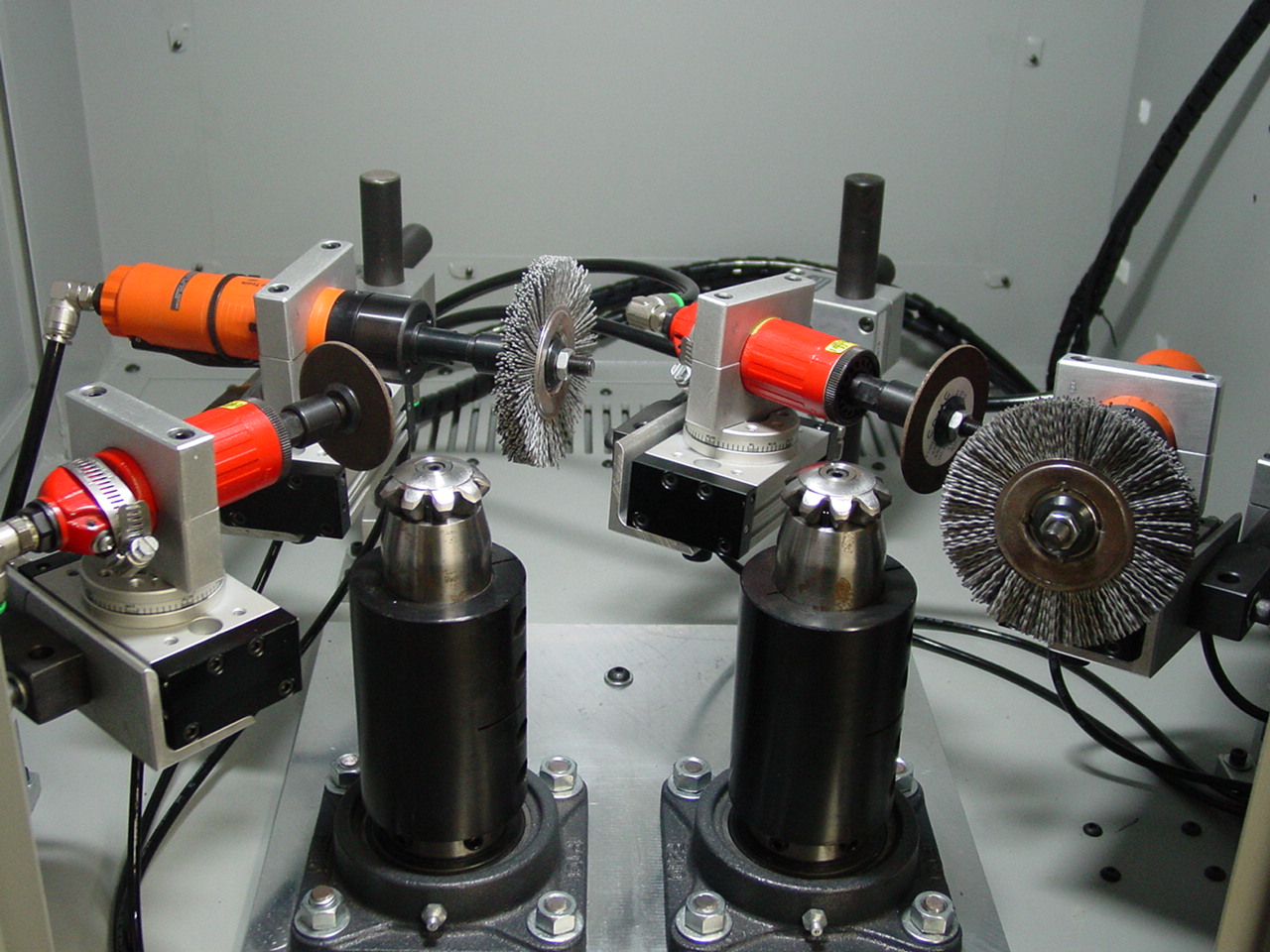

Our automated edge prep machines use nylon abrasive radial brushes for all applications. Special diamond brushes are available for enhanced capabilities and improved surface finishes. The variable speed brush motor is integral to the variable edge prep size and shape. These brushes, as well as other brush types, can be used for polishing. Wheel packs can be specific to tools, or a common wheel pack used for all operations.

Technical Data

- Round tools from .125” – 1.00” (3mm – 25mm) diameter up to 8.0” (200 mm) length standard

- Turnkey system

- Six-axis servo operation to achieve virtually any edge prep

- Single brush or multiple brushes – wheel packs are available

- Flute polishing capability

- Special and step tools with unique features

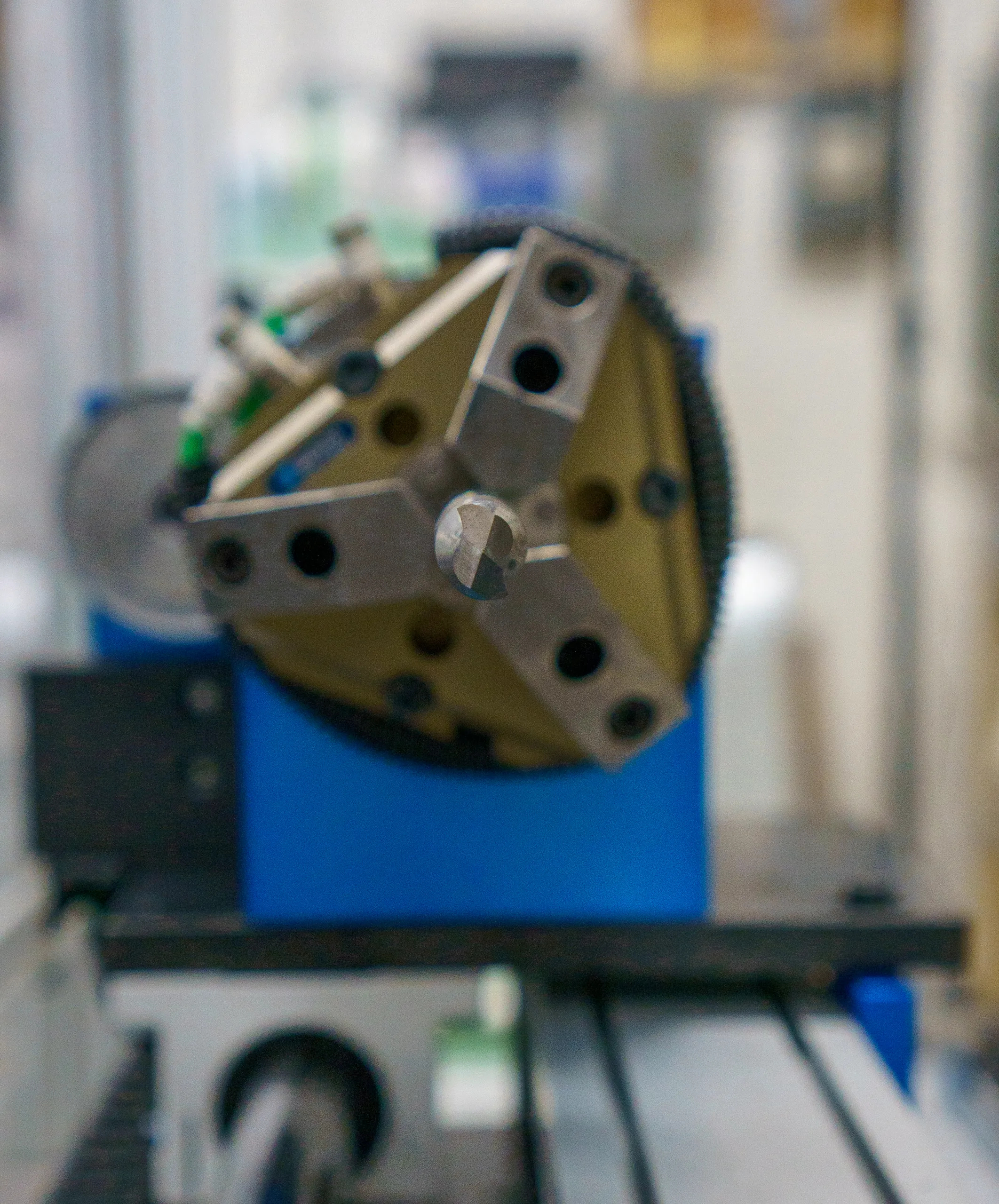

- Three-jaw manual chuck with optional through-hole capability

- Gun drill options available

- Optional Pneumatic chuck with .125” – 1.000” (3mm – 25mm) jaws supplied

- 110 VAC operation

- 700-part recipes can be stored

- Round tools from .125” – 1.00” (3mm – 25mm) diameter up to 8.0” (200 mm) length standard

- Turnkey system

- Six-axis servo operation to achieve virtually any edge prep

- Single brush or multiple brushes – wheel packs are available

- Flute polishing capability

- Easy operation with tool-specific recipe options

- Special and step tools with unique features

- Pneumatic Schunk gripper chuck with .125” – 1.000” (3mm – 25mm) jaws supplied

- 220 VAC operation

- 700-part recipes can be stored

- 80 PSI (5.5 BAR) air required/Air prep system included

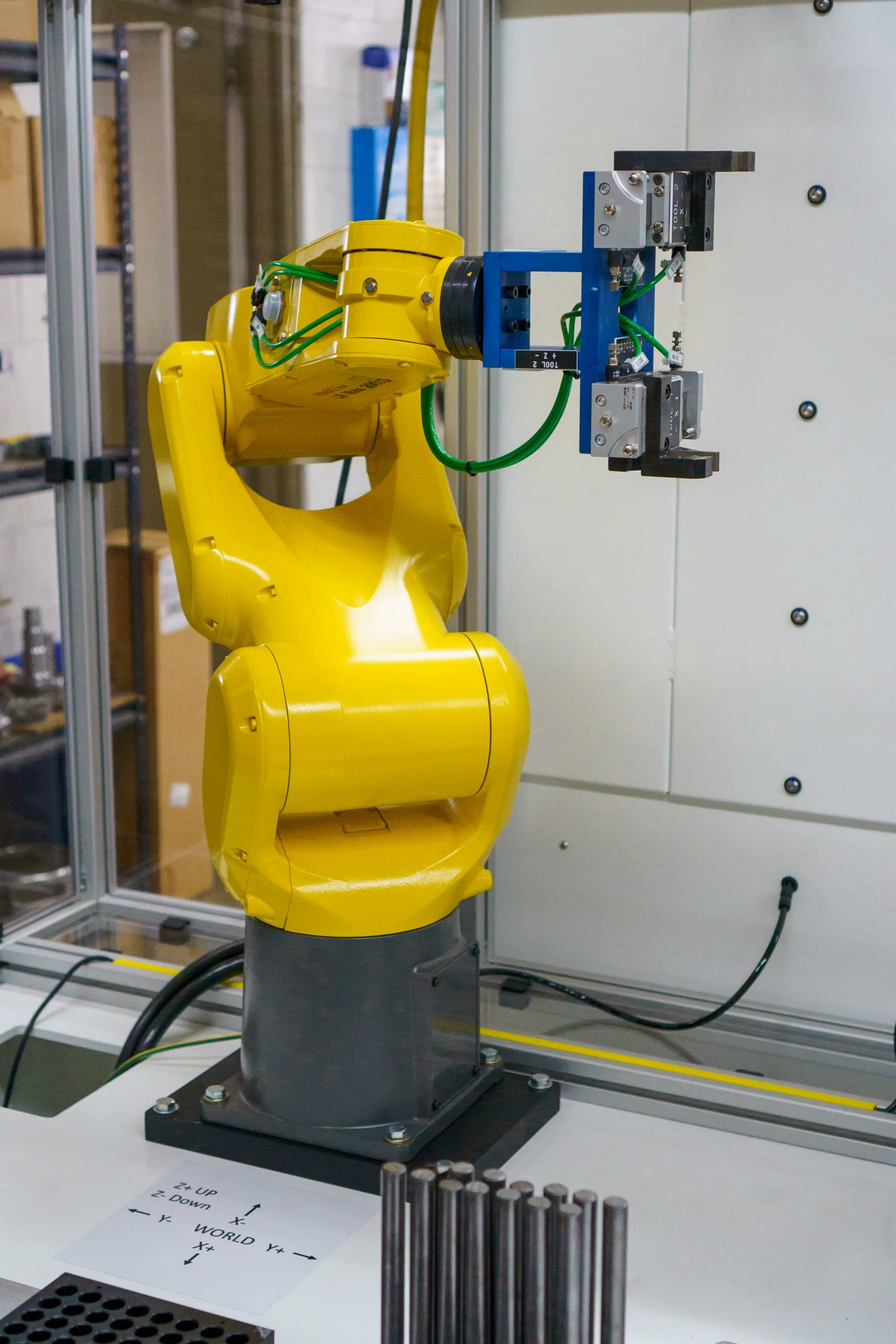

- Fanuc LR 200 robot with simple program options

- 100 pallet options can be stored

- Lights-out capability

Standard Models or Built to Specifications

Automation solutions may be built to customer specifications. Both custom and standard models are shipped as turnkey solutions. Toolink Engineering will also provide installation, training, and support with each purchase.

About MET

MET is a family-owned and operated company located in Cleveland, OH in our 20,000-square-foot manufacturing facility. We design and build our systems in Cleveland and welcome you to visit to meet our team and tour our plant. MET consists of Adam Mutschler, Applications and Marketing Manager, Christopher Mutschler, Manufacturing Manager, and Eric Mutschler, Applications and Engineering. Our staff of ten allows us to oversee the quality of our machines and continually improve their capabilities.

Get Social